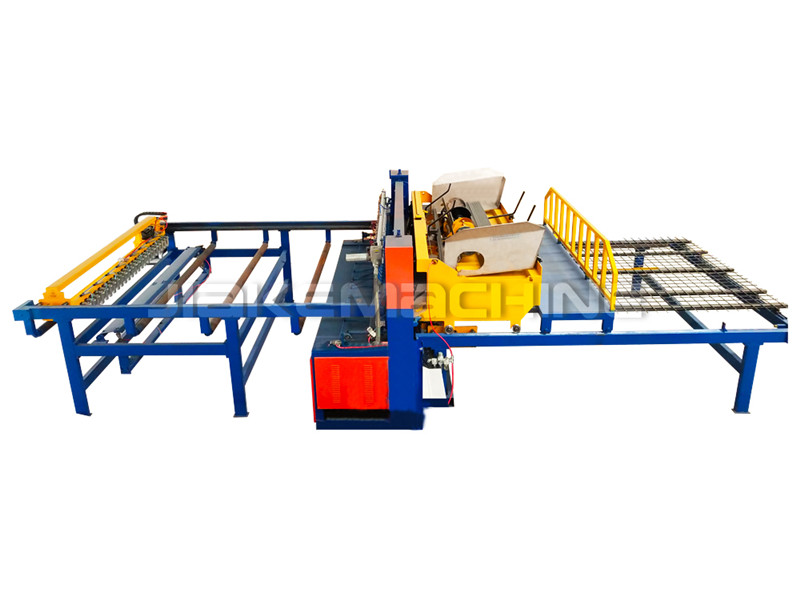

2020 Latest Design Woven Steel Mesh Panels Machine - Roll Mesh Welded Machine – Jiake

2020 Latest Design Woven Steel Mesh Panels Machine - Roll Mesh Welded Machine – Jiake Detail:

3-6mm wire mesh welding machine, used for making roof mesh, road mesh, construction mesh, 3-6mm wire, finished mesh in roll;

1.Technical Parameter:

| Model | DP-2500BN |

| Wire diameter | 3-6mm/ 2.5-6mm |

| Line wire space | 50-300mm (adjustable) |

| Cross wire space | Min. 50mm (adjustable) |

| Mesh width | Max. 2500mm |

| Mesh roll length | Max. 100m (mostly is 30-50m/ roll) |

| Welding speed | Max. 75 times/ min |

| Production | 1800m/ 8 hours |

| Finished mesh | Can be roll mesh and panel mesh, according to your needs |

| Electrodes | 48 pcs |

| Welding transformer | 150kva* 6 pcs |

| Machine dimension | 6.9* 3.4 *1.8 m |

| Machine weight | 6.5 t |

| Working space | 21*5 meter |

| Worker | 2-3 |

| Controlled | PLC+ touch screen |

| Voltage | As your required |

| Power supply | Min. 160kva |

| Packing | 1* 40ft container |

2.YouTube Video

3.Superiorities of welded mesh production line

Main electric components:

●Panasonic (Japan) PLC

●Weinview (Taiwan) touch screen

●Schneider (France) low-voltage apparatus

●ABB (Switzerland Sweden) switch

●Schneider (France) air switch

●Omron (Japan) power supply

●Delta (Taiwan) Variable-frequency Drive

●Autonics (South Korea) encoder

●Panasonic (Japan) servo drive

Main Technologies:

●Welding electrodes are made of pure copper (upper Φ20*120mm, lower 20*20*20mm), durable.

●Main motor (5.5kw)&Helical gear reducer connects the main axis directly, big.

●Cast water-cooling transformers, high efficiency. The welding degree is adjusted by PLC.

●SMC (Japan) air cylinders & pneumatic parts, machine working more stable.

●Panasonic (Japan) servo motor & planetary reducer for pulling mesh, more precise.

●The cable carrier is the Igus brand, imported from Germany, the best one all over the world, not hanging down.

Wire feeding way:

●Line wires are fed from wire coils automatically and through precise straight setting equipment.

●Cross wires should be pre-straightened&pre-cut, then fed from hopper device automatically. The hopper device is controlled by the step motor and SMC air cylinder, has a high capacity.

4.Finished Rolled Mesh

3-6mm wire mesh welding machine, used for making roof mesh, road mesh, construction mesh, 3-6mm wire, finished mesh in roll.

Product detail pictures:

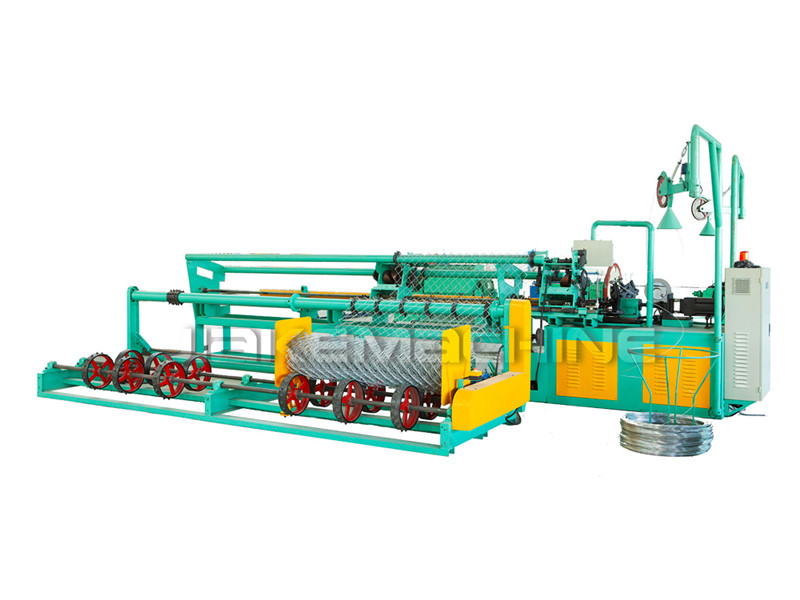

Related Product Guide:

In order to give you convenience and enlarge our business, we also have inspectors in QC Team and assure you our best service and product for 2020 Latest Design Woven Steel Mesh Panels Machine - Roll Mesh Welded Machine – Jiake , The product will supply to all over the world, such as: Mauritius, Barbados, Ecuador, Regarding quality as survival, prestige as guarantee, innovation as motive force, development along with advanced technology, our group hopes to make progress together with you and make untiring efforts for the bright future of this industry.

The customer service reprersentative explained very detailed, service attitude is very good, reply is very timely and comprehensive, a happy communication! We hope to have a opportunity to cooperate.