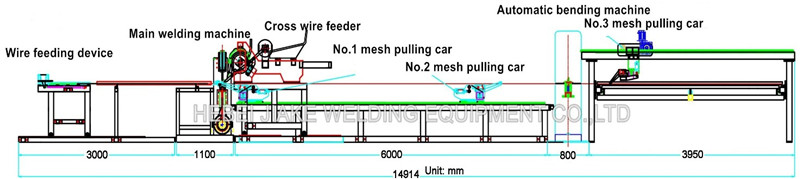

3D Fence Welded Mesh Machine

Fence panel welded mesh processing flow

1) After finish welding, No.1 mesh pulling car will pull the mesh to the position of No.2 mesh pulling car.

2) No.2 mesh pulling car will pull the mesh to the bending machine step by step to finish the bending.

3) After finish the bending, No.3 mesh pulling car will pull the mesh to the mesh falling part.

1.Technical Parameter:

| Model | DP-FP-1200A | DP-FP-2500A | DP-FP-3000A |

| Welding width | Max.1200mm | Max.2500mm | Max.3000mm |

| Wire diameter | 3-6mm | ||

| Longitude wire space | 50-300mm | ||

| Cross wire space | Min.25mm/Min.12.7mm | ||

| Mesh length | Max.6000mm | ||

| Welding speed | 50-75 times/min | ||

| Wire feeding way | Pre-straightened & pre-cut | ||

| Welding electrodes | Max.25pcs | Max.48pcs | Max.61pcs |

| Welding transformers | 125kva*3pcs | 125kva*6pcs | 125kva*8pcs |

| Machine size | 4.9*2.1*1.6m | 4.9*3.4*1.6m | 4.9*3.9*1.6m |

| Weight | 2T | 4T | 4.5T |

| NOTE: Special specification can be customized as your request. | |||

2.YouTube Video

3.Superiorities of fence panel welding production line

● Touch screen interface control with minimized workers’ operation to save your cost-efficiently.

● The electrical system from Panasonic, Schneider, ABB, Igus for the reliable control system.

● Patent technology motor system for fast rotation and high productivity.

● Mesh welding and output controlled by windows interface, high automation.

● Servo pulling system for small and large batch sizes for different market demands.

● Water-cooling system to decease welding temperature and for mesh flatness efficiently.

● Complete product solutions according to your request for an automation degree.

● More-than-30-years’ experience on mesh welding machine to serve customers practically.

4.Finished Fence Panel Mesh