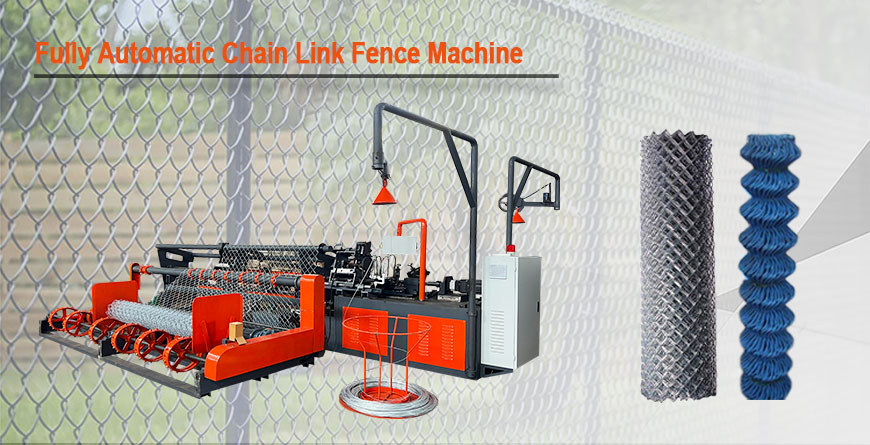

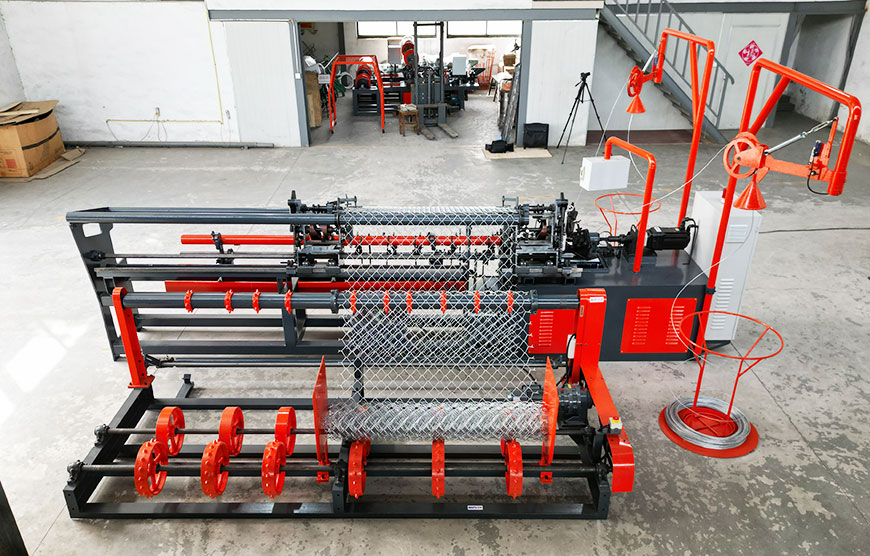

Fully Automatic Chain Link Fence Machine

· High speed

· Fully automatic

· Good brand motor

· Famous brand electric components

Fully automatic chain link fence machine have three types, single wire type chain link fence machine, double wire chain link fence machine and double motor chain link fence machine. Those machines can produce diamond fences quickly and efficiently, and are running smoothly and with reliable performance, the product is flat.

Double wire chain link fence machine(DP25-100)

Double motor chain link fence machine(DP20-100D)

Single wire chain link fence machine(DP20-100S)

Chain link fence machine parameter

| Model | DP25-100(double wire) | DP20-100D(double motor) | DP20-100S(single wire) |

| Wire diameter | 1.8-4.0mm | 1.5-4.5mm | 1.5-4.0mm |

| Mesh opening | 25-100mm | 20-100mm | 20-100mm |

| Mesh width | Max. 3m/4m | Max. 3m/4m (can design 6m width if you need) | |

| Mesh length | Max.30m, adjustable | ||

| Raw material | Galvanized wire or PVC coated wire | ||

| Servo motor | 5.5kw | 2pcs of 4.5kw | 4.5kw |

| Weight | 3900KGS/4200KGS | 3200KGS/3500KGS | 2200KGS/2500KGS |

Chain link fence machine advantages

|

Main Electronics |

|

| Machine electronic components equips good brand like Japan Mitsubishi, France Schneider very easy to operate, making the service life of machine longer. | |

| Touch screen control | France Schneider switch/ Japan Mitsubishi PLC |

|

|

|

| Japan Omron Power supply | France Schneider transformer |

|

|

|

|

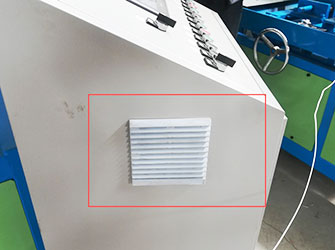

Easy connection with air outlet opening and Plug pins |

|

| We designed air outlet opening on the electric cabinet, making the air cooling itself.We collect almost all electric wires in plug pins, which make it easier to install in electronics. | |

|

|

|

|

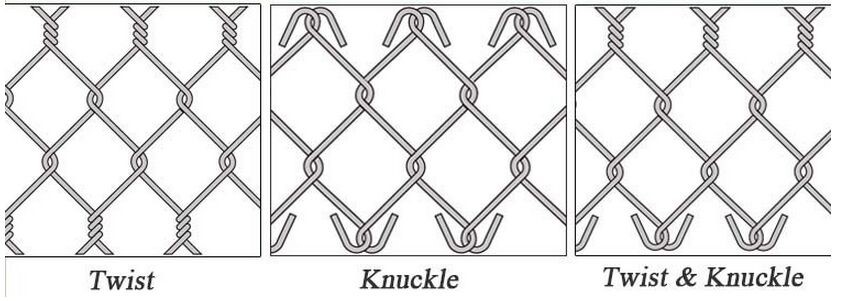

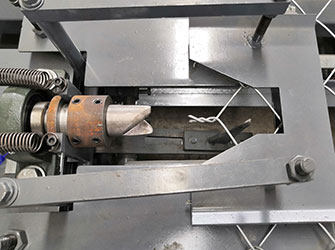

Automatic rolling and dealing mesh ends |

|

| The machine is fully automatic (feeding wire, twist/ knuckle sides, winding up rolls).Mesh ends can be Twist, Knuckle or Twist and Knuckle as your request | |

|

|

|

|

|

|

|

Different mesh rolling system (Optional) |

|

| Compactor | Mesh rolling machine |

|

|

|

Chain link fence machine Video

Sales-after service

|

We will provide a full set of installation videos about the concertina razor barbed wire making machine

|

Provide the layout and electrical diagram of the concertina barbed wire production line |

Provide installation instruction and manual for automatic security razor wire machine |

Answer every question online 24 hours a day and talk to professional engineers |

Technical personnel go abroad to install and debug razor barbed tape machine and train workers |

Equipment maintenance

|

A. Lubrication liquid is added regularly. B. Checking electric cable connection every month. |

Chain link fence machines - client feedback

One Indian customer bought 2 sets of machines in 2018, which have been working great until now.

Certification

Chain link fence application

FAQ

What are the accepted payment methods?

A: T/T or L/C is acceptable. 30% in advance, we start produce machine. After machine finished, we will send you testing vide or you could come to check machine. If satisfied with machine, arrange balance 70% payment. The we can loading machine to you.

How to transport different type of machine?

A: Normally 1 set of machine need one 20GP container. 1x40HQ container can hold 4 sets of single wire type machine, 2 sets of double wire type machine.

The production cycle of the razor barbed wire machine?

A:20-30days

How to replace worn parts?

A: We have free spare part box loading together with machine. If there is other parts needed, normally we have stock, will send to you in 3 days.

How long is the warranty period of the razor barbed wire machine?

A: 1 year after the machine arrive in your factory. If the main part broken because of quality, not manually mistake operation, we will send you replace part for free.

Can I make compact the rolls smaller to save place?

A: Yes, the mesh rolling way have 2 type, normal rolls and compacted rolls.