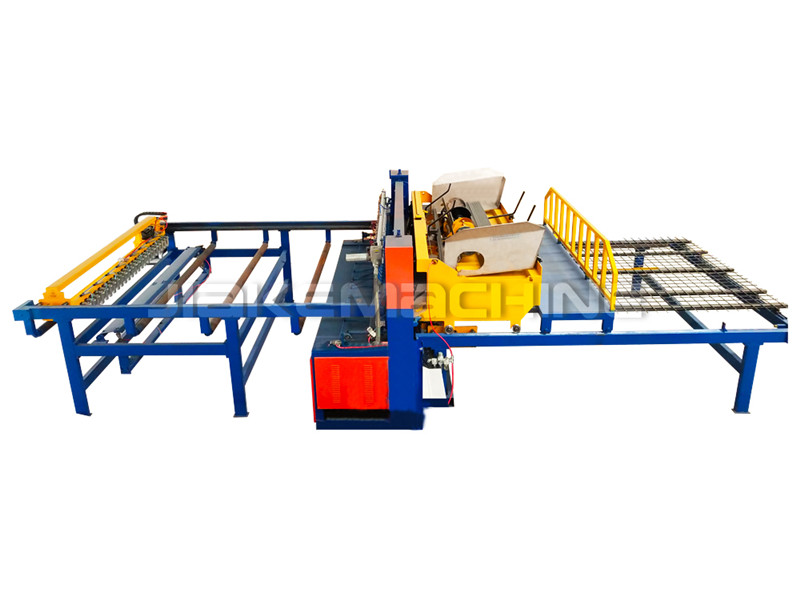

High Quality for Welded Mesh Galvanized Sheets Machine - Welded Wire Mesh Machine – Jiake

High Quality for Welded Mesh Galvanized Sheets Machine - Welded Wire Mesh Machine – Jiake Detail:

Our Automatic Welded Wire Mesh Machine is equipped with an Automatic Cross-wire feeding system, Auto coiling/rolling system, and Auto roll-out system. Equipped with middle cutter and side cutters to make two mesh rolls one time. Separate control technology, reduce the impact current and guarantee welding solid.

The Panasonic 4.5KW servo driver with rubber shaft is more accurate and stable. PLC (Mitsubishi-Japan) control system with touch screen (Weview-Taiwan brand) input, which makes the operation more intelligent and convenient.

1.Technical Parameter:

| Model | DP-DNW-1 | DP-DNW-2 | DP-DNW-3 | DP-DNW-4 |

| Wire diameter | 0.4-0.65mm | 0.65-2mm | 1.0-2.8mm | 1.6-3mm |

| Line wire pitch | (6.25mm,12.5mm) | (12.5mm,25mm,50mm) | (25-150mm) | 25mm, 30mm |

| Cross wire pitch | (6.25mm,12.5mm) | (12.5mm,25mm,50mm) | (12.5-150mm) | Min.25mm |

| Mesh width | 0.9m, 1.2m | 1.2m, 1.5m, 2m | 1.5m, 2m, 2.5m | Max. 2m |

| Main motor | 2.2kw | 2.2kw, 4kw, 5.5kw | 4kw, 5.5kw, 7.5kw | 5.5kw(Panasonic) |

| Welding transformer | 60kva*3*4pcs | 60-80kva*4/5/7pcs | 80-100kva*5/7/8pcs | 125KVA*6 |

| Welding speed | Max.80times/min | Max.120-180times/min | Max.60-100 times/min | 60-100times/min |

| Weight | 2T/2.5T | 2.5T/3T/3/5T | 3T/3.5T/4T | 3.5T |

NOTE: We can customize the machine according to your requirements for wire diameter and mesh.

2.YouTube Video

3.Superiorities of Welded wire mesh machine

Taiwan Weinview Touch Screen + Japan Mitsubishi PLC, easy operation.

Cross wire feeding controlled by Servo motor, faster and more precise.

Mesh pulling rubber rollers controlled by Delta Servo motor, working smooth.

Taiwan Delta Inverter control motor working, speed adjustable.

Japan SMC air cylinder + Electromagnetic valve for cross wire feeding, working precise and smooth.

Welding currency and welding time can be adjusted through Touch screen + PLC, easily.

Mesh rolling machines can take up rolls and discharge rolls automatically.

Both longitude wire and cross wire are fed from wire coils automatically.

4.Finished Rolled Mesh

Product detail pictures:

Related Product Guide:

We believe in: Innovation is our soul and spirit. Top quality is our life. Purchaser need is our God for High Quality for Welded Mesh Galvanized Sheets Machine - Welded Wire Mesh Machine – Jiake , The product will supply to all over the world, such as: Botswana, Serbia, New Orleans, After 13 years of researching and developing products, our brand can represent wide range of products with outstanding quality in world market. We have completed big contracts from many countries such as Germany, Israel, Ukraine, United Kingdom, Italy, Argentina, France, Brazil, and so on. You probably feel secure and satisfy when copperate with us.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.