As the global construction industry’s demand for efficient and precise reinforcement materials continues to increase, the 3-6mm construction mesh welding machine, as a device for the automated production of construction meshes, has become an important equipment in construction projects with its precise welding technology and the ability to produce both construction mesh sheets and rolled meshes.

Recently, DAPU Factory successfully sold a 3-6mm construction mesh welder to Brazil, which will be used for domestic infrastructure construction in Brazil, especially in the production of steel mesh for highways, bridges, and large commercial buildings.

Equipment Overview

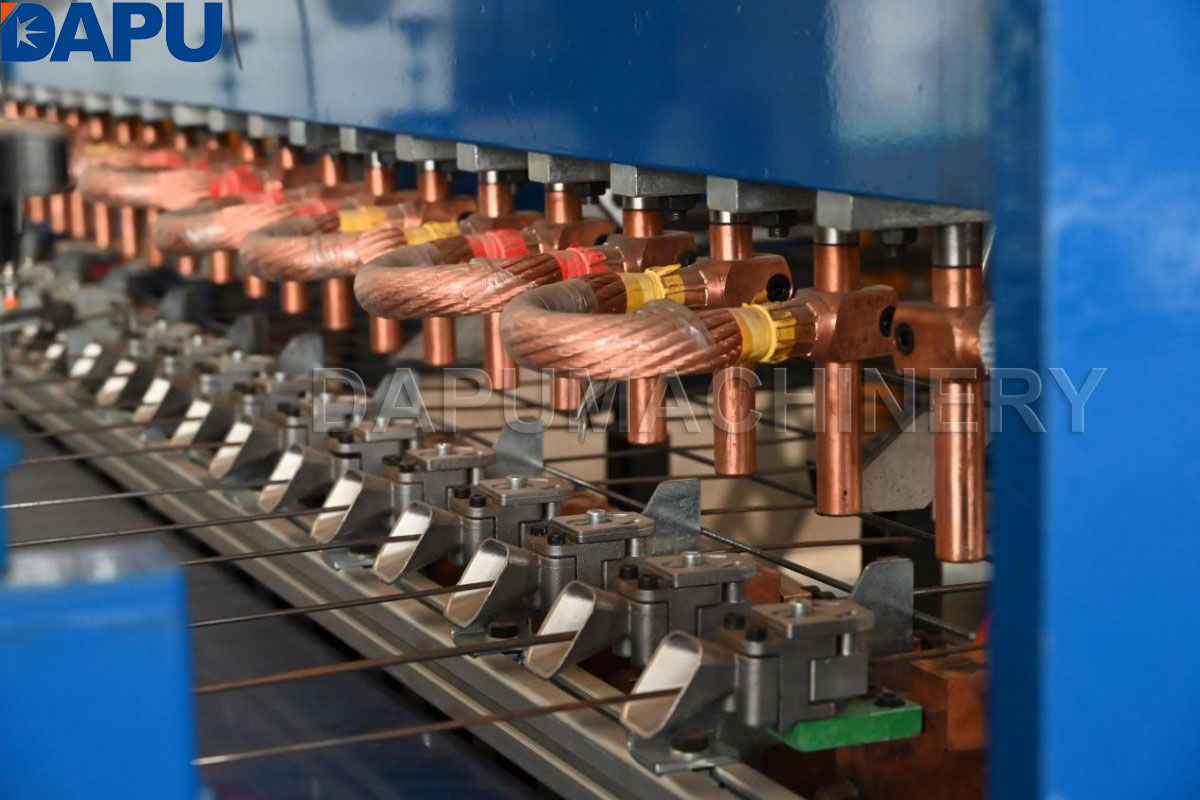

The 3-6mm roll mesh welding machine is designed for the production of 3 to 6 mm diameter steel meshes and is suitable for the production of steel meshes used for concrete reinforcement in projects such as buildings, bridges, and highways. The equipment heats the steel bars through high-frequency current and performs efficient and stable welding at the welding points to ensure the strength and consistency of each welding point. The equipment’s automated control system makes operation easier, and can flexibly adjust the mesh size, steel bar spacing, and welding density to meet the needs of different projects.

Machine video:

Brazilian market demand

As the largest economy in Latin America, Brazil has accelerated its infrastructure construction and urbanization in recent years, especially in the fields of transportation, energy, and construction, and the demand for construction steel mesh has increased. With the construction of new highways, bridges, and urban renewal projects in Brazil, the demand for construction mesh has also surged. In this context, the import of 3-6mm construction mesh welding machines is particularly important, which will greatly improve the production efficiency and quality of construction mesh, help local construction companies in Brazil improve productivity, shorten project cycles, and reduce labor costs.

Transportation and delivery

In order to ensure that the equipment can be transported smoothly and delivered on time, the RKM Factory team worked closely with logistics partners to develop a detailed transportation plan. Due to the diversity of Brazil’s geographical environment and infrastructure, the team paid special attention to the details of transportation, such as customs procedures, port scheduling, and the safety of the final delivery location. During transportation, all equipment was strictly packaged and inspected to ensure that it would not be damaged during long-distance transportation. In the end, the equipment arrived in Brazil on time and was successfully delivered to local customers after customs clearance.

If you want more information about the 3-6mm construction mesh welding machine, please contact us now!

Mobile/WeChat/WhatsApp NO.: +86 181 3380 8162

Email: sales@jiakemeshmachine.com

Customer feedback

Brazilian customers highly praised the quality and performance of the 3-6mm construction mesh welder, believing that the equipment can greatly improve the production efficiency of the steel mesh, and the welding quality is very stable, ensuring the quality requirements of the project. Brazilian customers will purchase steel mesh welders in large quantities in 2025 to improve production efficiency. Customers said that with the commissioning of this equipment, the production of construction steel mesh in the Brazilian market will enter a new stage of development, which will help improve the production level of the entire industry.

Post time: Dec-09-2024