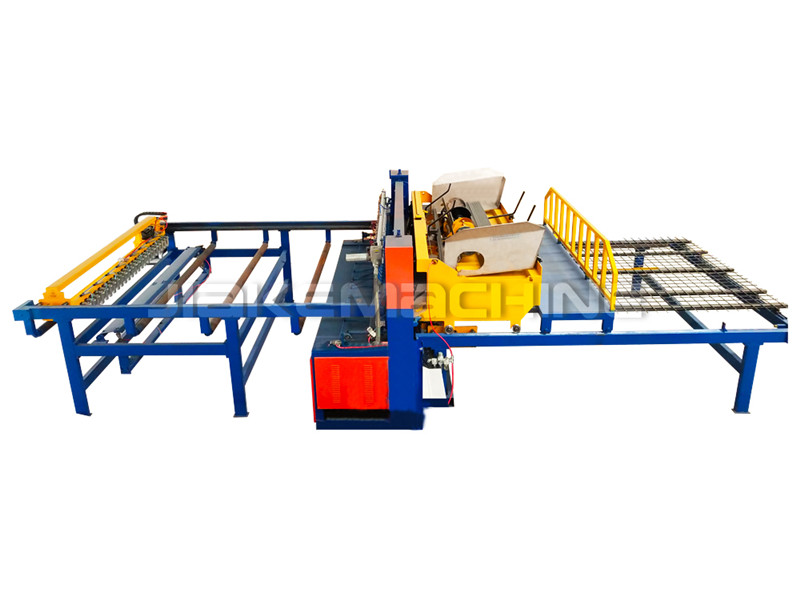

OEM Supply Mesh Fence Panels Machine - Roll Mesh Welded Machine – Jiake

OEM Supply Mesh Fence Panels Machine - Roll Mesh Welded Machine – Jiake Detail:

3-6mm wire mesh welding machine, used for making roof mesh, road mesh, construction mesh, 3-6mm wire, finished mesh in roll;

1.Technical Parameter:

| Model | DP-2500BN |

| Wire diameter | 3-6mm/ 2.5-6mm |

| Line wire space | 50-300mm (adjustable) |

| Cross wire space | Min. 50mm (adjustable) |

| Mesh width | Max. 2500mm |

| Mesh roll length | Max. 100m (mostly is 30-50m/ roll) |

| Welding speed | Max. 75 times/ min |

| Production | 1800m/ 8 hours |

| Finished mesh | Can be roll mesh and panel mesh, according to your needs |

| Electrodes | 48 pcs |

| Welding transformer | 150kva* 6 pcs |

| Machine dimension | 6.9* 3.4 *1.8 m |

| Machine weight | 6.5 t |

| Working space | 21*5 meter |

| Worker | 2-3 |

| Controlled | PLC+ touch screen |

| Voltage | As your required |

| Power supply | Min. 160kva |

| Packing | 1* 40ft container |

2.YouTube Video

3.Superiorities of welded mesh production line

Main electric components:

●Panasonic (Japan) PLC

●Weinview (Taiwan) touch screen

●Schneider (France) low-voltage apparatus

●ABB (Switzerland Sweden) switch

●Schneider (France) air switch

●Omron (Japan) power supply

●Delta (Taiwan) Variable-frequency Drive

●Autonics (South Korea) encoder

●Panasonic (Japan) servo drive

Main Technologies:

●Welding electrodes are made of pure copper (upper Φ20*120mm, lower 20*20*20mm), durable.

●Main motor (5.5kw)&Helical gear reducer connects the main axis directly, big.

●Cast water-cooling transformers, high efficiency. The welding degree is adjusted by PLC.

●SMC (Japan) air cylinders & pneumatic parts, machine working more stable.

●Panasonic (Japan) servo motor & planetary reducer for pulling mesh, more precise.

●The cable carrier is the Igus brand, imported from Germany, the best one all over the world, not hanging down.

Wire feeding way:

●Line wires are fed from wire coils automatically and through precise straight setting equipment.

●Cross wires should be pre-straightened&pre-cut, then fed from hopper device automatically. The hopper device is controlled by the step motor and SMC air cylinder, has a high capacity.

4.Finished Rolled Mesh

3-6mm wire mesh welding machine, used for making roof mesh, road mesh, construction mesh, 3-6mm wire, finished mesh in roll.

Product detail pictures:

Related Product Guide:

We now have a highly efficient crew to deal with inquiries from clients. Our intention is 100% shopper pleasure by our merchandise quality, price tag & our staff service and take pleasure in a very good standing amongst purchasers. With quite a few factories, we can easily provide a wide vary of OEM Supply Mesh Fence Panels Machine - Roll Mesh Welded Machine – Jiake , The product will supply to all over the world, such as: Rotterdam, Bulgaria, Egypt, Excellent quality, competitive price, punctual delivery and dependable service can be guaranteed. For further inquires please do not hesitate to contact us. Thank you - Your support continuously inspires us.

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.