OEM/ODM Factory Welded Wire Mesh Manufacturing Machine - Welded Wire Mesh Machine – Jiake

OEM/ODM Factory Welded Wire Mesh Manufacturing Machine - Welded Wire Mesh Machine – Jiake Detail:

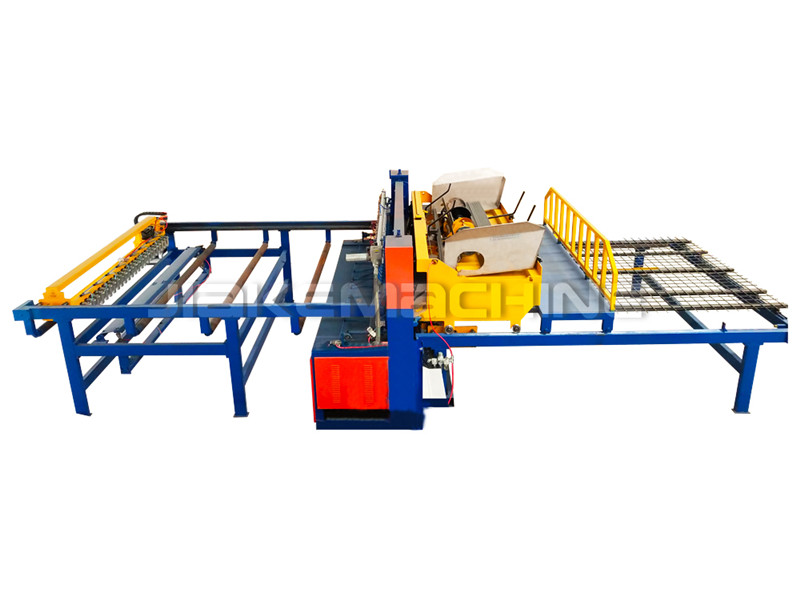

Our Automatic Welded Wire Mesh Machine is equipped with an Automatic Cross-wire feeding system, Auto coiling/rolling system, and Auto roll-out system. Equipped with middle cutter and side cutters to make two mesh rolls one time. Separate control technology, reduce the impact current and guarantee welding solid.

The Panasonic 4.5KW servo driver with rubber shaft is more accurate and stable. PLC (Mitsubishi-Japan) control system with touch screen (Weview-Taiwan brand) input, which makes the operation more intelligent and convenient.

1.Technical Parameter:

| Model | DP-DNW-1 | DP-DNW-2 | DP-DNW-3 | DP-DNW-4 |

| Wire diameter | 0.4-0.65mm | 0.65-2mm | 1.0-2.8mm | 1.6-3mm |

| Line wire pitch | (6.25mm,12.5mm) | (12.5mm,25mm,50mm) | (25-150mm) | 25mm, 30mm |

| Cross wire pitch | (6.25mm,12.5mm) | (12.5mm,25mm,50mm) | (12.5-150mm) | Min.25mm |

| Mesh width | 0.9m, 1.2m | 1.2m, 1.5m, 2m | 1.5m, 2m, 2.5m | Max. 2m |

| Main motor | 2.2kw | 2.2kw, 4kw, 5.5kw | 4kw, 5.5kw, 7.5kw | 5.5kw(Panasonic) |

| Welding transformer | 60kva*3*4pcs | 60-80kva*4/5/7pcs | 80-100kva*5/7/8pcs | 125KVA*6 |

| Welding speed | Max.80times/min | Max.120-180times/min | Max.60-100 times/min | 60-100times/min |

| Weight | 2T/2.5T | 2.5T/3T/3/5T | 3T/3.5T/4T | 3.5T |

NOTE: We can customize the machine according to your requirements for wire diameter and mesh.

2.YouTube Video

3.Superiorities of Welded wire mesh machine

Taiwan Weinview Touch Screen + Japan Mitsubishi PLC, easy operation.

Cross wire feeding controlled by Servo motor, faster and more precise.

Mesh pulling rubber rollers controlled by Delta Servo motor, working smooth.

Taiwan Delta Inverter control motor working, speed adjustable.

Japan SMC air cylinder + Electromagnetic valve for cross wire feeding, working precise and smooth.

Welding currency and welding time can be adjusted through Touch screen + PLC, easily.

Mesh rolling machines can take up rolls and discharge rolls automatically.

Both longitude wire and cross wire are fed from wire coils automatically.

4.Finished Rolled Mesh

Product detail pictures:

Related Product Guide:

Well-run devices, expert profits group, and better after-sales companies; We have been also a unified huge family, everybody keep on with the organization worth unification, determination, tolerance for OEM/ODM Factory Welded Wire Mesh Manufacturing Machine - Welded Wire Mesh Machine – Jiake , The product will supply to all over the world, such as: Juventus, Netherlands, Germany, We'll continue to devote ourselves to market & product development and build a well-knit service to our customer to create a more prosperous future. Please contact us today to find out how we can work together.

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.