Reinforcing Mesh Welding Machine

· 3-12mm wire diameter workable;

· 80-120 times/ min welding speed;

· Europe design

DAPU factory is a gold manufacturer of steel mesh welding machines in China, we have more than 30 years of production experience, in order to provide customers with better solutions, we have integrated European welding technology, faster and more efficient welding mesh, and we Famous foreign electronic components are also used to achieve the purpose of fewer failures and long service life of the machine.

Reinforcing Mesh Welding Machine Advantages:

1. Easier machine maintenance, less machine problem.

2. Same welding pressure for each welding point, guaranteeing welding quality.

3. Enough welding power to weld max.12mm rebar.

4. The welding speed can be up to a max of 80-100 times/min.

5. Easily adjust the line wire space, For the welding electrode no need to work, only need to disconnect the electromagnetic valve.

6. Precision pressure reduction valve, ±0.5% error. High flow..

Reinforcing Mesh Welding Machine Parameter:

| Model | DP-GW-2500B |  |

| Wire diameter | 4-12mm | |

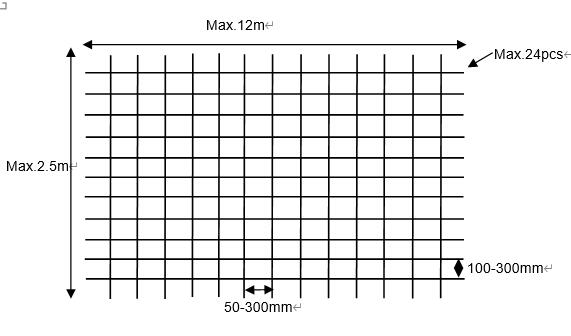

| Line wire space | 100-300mm | |

| Cross wire space | 50-300mm | |

| Width of mesh | 1200-2500mm | |

| Length of mesh | 1.5-12m | |

| Welding electrodes | 24pcs | |

| Welding transformer | 150kva*12pcs | |

| Welding speed | Max.80-100 times/min | |

| Line wire feeding | Pre-straightened&pre-cut | |

| Cross wire feeding | Pre-straightened&pre-cut | |

| Air compressor | Less than 3.7m^3/min | |

| Weight | 7.3T | |

| Machine size | 22*3.5*2.3m |

Reinforcing Mesh Welding Machine Video:

DAPU reinforcement mesh panel welder DP-GW-2500B, is jointly developed with the European technical team;

Line wire feeding part, is automatic feeding car, save time;

Welding part, we equipped SMC (Japan) customized 90 multi-force air cylinder, Output power increase 20%. Air consumption save 30%.

Mesh pulling part equipped Panasonic servo motor, pulling speed is faster and pulling distance is more accurate;

Mesh falling part we have automatic falling and pulling out device, this is optional device;

DAPU mesh welded machine, with Europe design and Chinese price;

Sales-after service

|

We will provide a full set of installation videos about the concertina razor barbed wire making machine

|

Provide the layout and electrical diagram of the concertina barbed wire production line |

Provide installation instruction and manual for automatic security razor wire machine |

Answer every question online 24 hours a day and talk to professional engineers |

Technical personnel go abroad to install and debug razor barbed tape machine and train workers |

Reinforcing Mesh Welding Machine for sales

|

|

| Australian customer customized reinforcing mesh welding machine | Engineers install and debug the reinforcing mesh welding machine in the customer's factory in Montenegro |

Reinforcing Mesh Application:

Reinforcement mesh is mainly used in building reinforcement and construction. Reinforcement mesh should have good adhesion with concrete grouting. Therefore, it is not recommended to use oily substances and paint on steel mesh. To prevent corrosion of steel structures, they should be installed completely immersed in concrete.

Certification

FAQ

1. Can i produce different reinforcement mesh size by same machine?

- Easily to make different size by same machine;

For line wire space, only need to turn off the electromagnetic valve of no need to worked electrodes;

For cross wire space, just set the size on touch screen (PLC) to adjust mesh pulling space is ok;

2. How much space required for this production line?

13*5meter is ok, but still depend on your requirement, we can design for you;

3. How long it will take for delivery?

Normally is 30-40 working days after receiving your advance payment;