Roll Mesh Welded Machine

Roll Mesh Welded Machine

An automatic welded wire mesh machine also called a roll mesh welding machine, is used to weld the wire with 3-6mm. Both the line wires and cross wires are fed automatically. The finished mesh of the machine can be both in roll and in panel.

Roll Mesh Welded Machine Parameter:

|

Model |

DP-FP-2500BN |

DP-FP-3000BN |

|

|

Mesh width |

Max. 2500mm |

Max. 3000mm |

|

|

Wire thickness |

3-6mm |

3-6mm |

|

|

Line wire space |

50-300mm |

100-300mm |

100-300mm |

|

Cross wire space |

50-300mm |

50-300mm |

|

|

Line wire feeding |

From coils automatically |

From coils automatically |

|

|

Line wire feeding |

Pre-cut, fed with hopper |

Pre-cut, fed with hopper |

|

|

Mesh length |

Panel mesh: max. 6m Roll mesh: max. 100m |

Panel mesh: max. 6m Roll mesh: max. 100m |

|

|

Working speed |

50-75times/min |

50-75times/min |

|

|

Welding electrodes |

51pcs |

24pcs |

31pcs |

|

Welding transformer |

150kva*6pcs |

150kva*6pcs |

150kva*8pcs |

|

Weight |

10T |

9.5T |

11T |

Roll Mesh Welded Machine Video:

Roll Mesh Welded Machine Advantages:

|

Electrical components: Panasonic (Japan) PLC Weinview (Taiwan) touch screen ABB (Switzerland Sweden) switch Schneider (France) low-voltage apparatus Schneider (France) air switch Delta (Taiwan) power supply Delta (Taiwan) inverter Panasonic (Japan) servo driver |

|

|

|

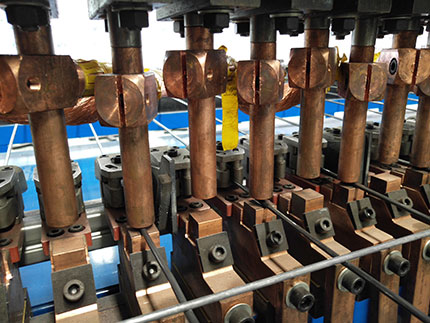

Welding electrodes are made of pure copper, working long life. |

|

Cross-wire falling is controlled by a step motor and SMC air cylinder, falling stable. |

|

|

|

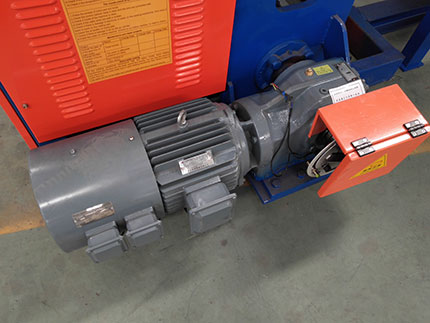

Main motor 5.5kw and level gear connect the main axis directly. |

|

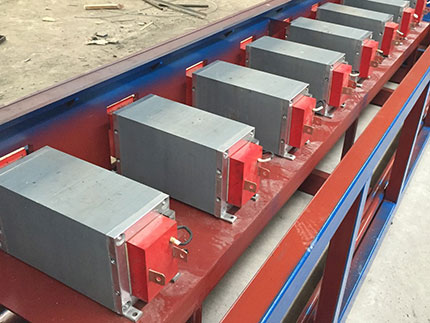

Cast water-cooling welding transformers, high efficiency. |

|

|

|

Panasonic (Japan) servo motor and planetary reducer for pulling mesh, more precise. |

Welded Mesh Application:

Welded mesh panel or rolls is polular used for concrete reinforcement in roof, floor, road, wall, etc.

Certification

Sales-after service

|

We will provide a full set of installation videos about the concertina razor barbed wire making machine

|

Provide the layout and electrical diagram of the concertina barbed wire production line |

Provide installation instruction and manual for automatic security razor wire machine |

Answer every question online 24 hours a day and talk to professional engineers |

Technical personnel go abroad to install and debug razor barbed tape machine and train workers |

Equipment maintenance

|

A. Slide part of the machine needs to add oil per week. Main axis needs to add oil per half year.

B. Clear dust and feculence on the electric control cabinet and machine regularly. C. Working environment above40℃,need air force cooling for the hot equipment. |

FAQ:

A:What's the price of the machine?

Q:It is different with the mesh opening size and mesh width you want.

A:If the mesh size can be adjusted?

Q:Yes, the mesh size can be adjusted within the range.

A:What's the delivery time of the machine?

Q:About 40 days after receiving your deposit.

A:What are the payment terms?

Q:30% T/T in advance, 70% T/T before shipment, or L/C, or cash, etc.

A:How many workers to operate the machine?

Q:Two or three workers

A: How long of the guarantee time?

Q:One year since the machine was installed at the buyer's factory but within 18 months against the B/L date.