Steel Rebar Stirrup Bending Machine

Steel Rebar Stirrup Bending Machine

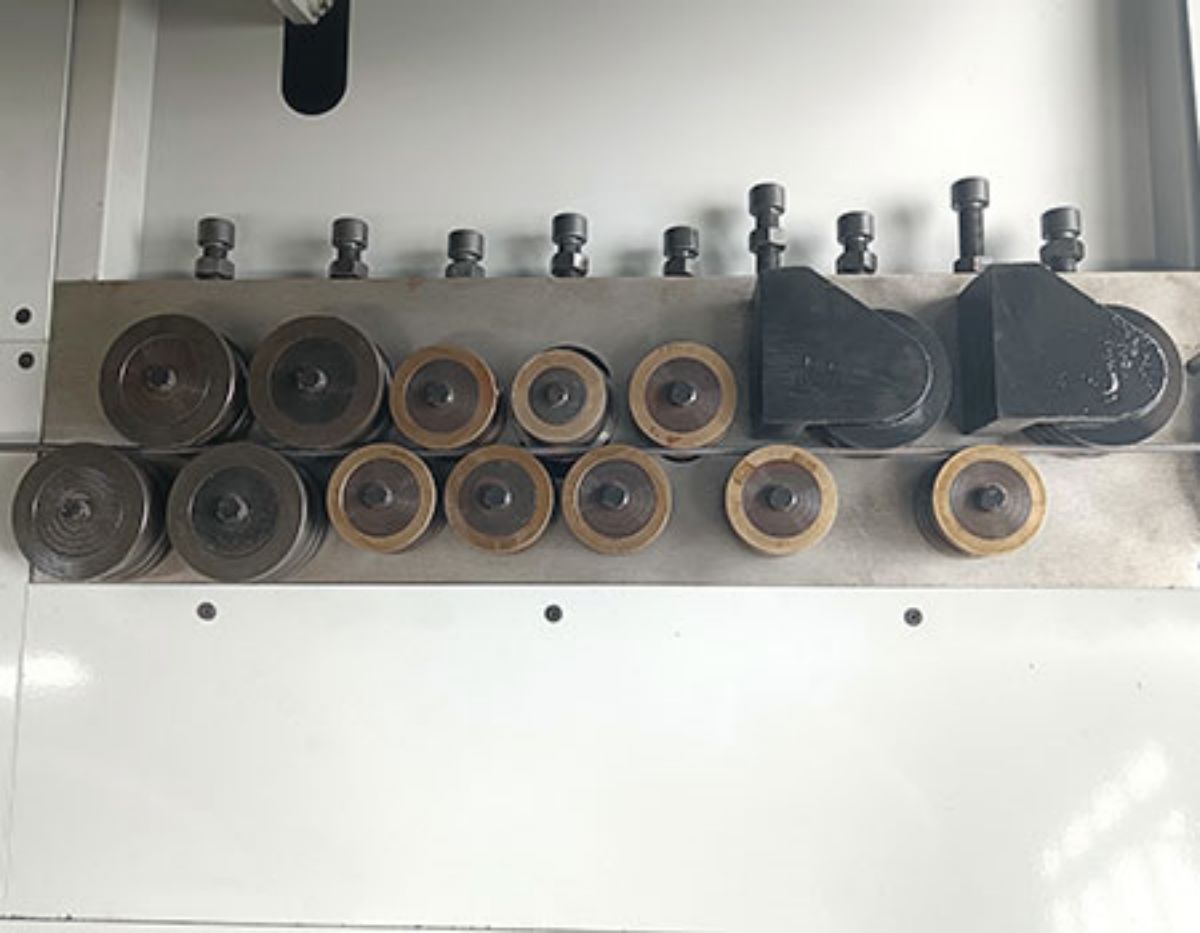

Double wire working, more efficiency;

60-110m/ min production

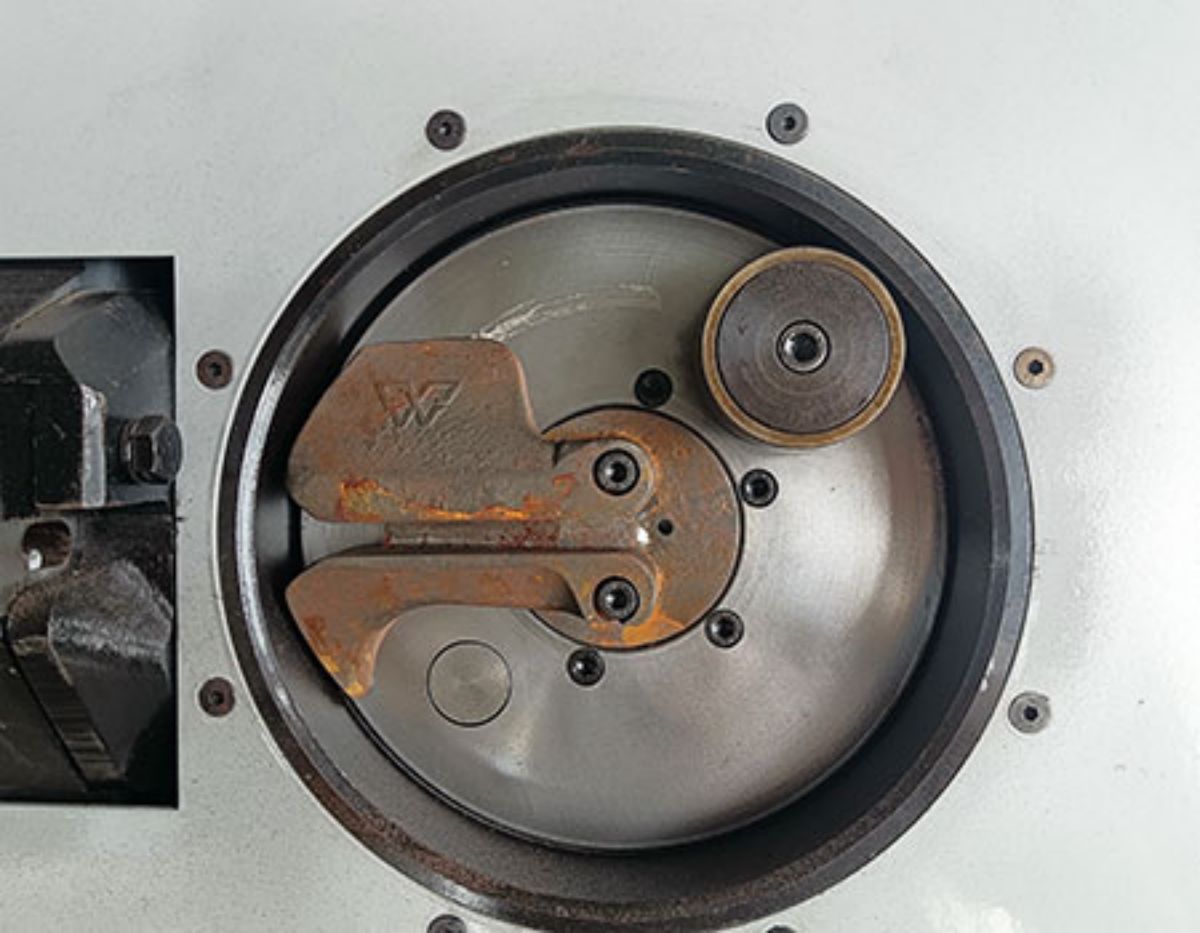

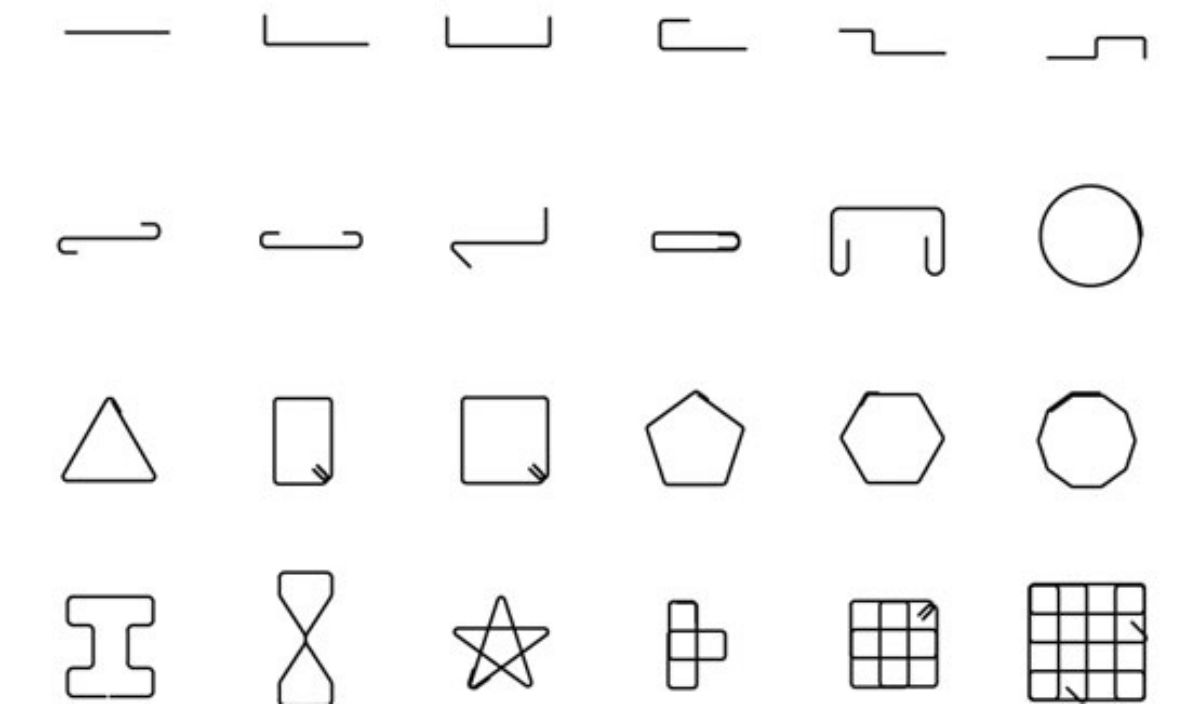

Various shape can be made easily from PLC system

DAPU rebar stirrup bender is newly hot-selling machinery; used to make different diameter and different shapes of rebar wire, for construction, like concrete slabs, floors, walls...etc;

This machine can produce double wire at the same time, highly output, more efficiency;

Also, we can provide different models of stirrup benders, to match your wire diameter;

We can set more than 100 shapes for your production, which can help you match different order demands;

DAPU will always provide a highly efficient after-sale service team with professional engineers and sales, making you Worry-free after-sales.

Machine Advantage:

Machine Parameter:

| Model | DP-KT2 | DP-KT3 |

| Single wire (mm) | Round wire 4-12 mmRibbed wire 4-10 mm | Round wire 5-14 mmRibbed wire 5-12 mm |

| Double wire (mm) | 4-8 mm | 5-10 mm |

| Max. Bending angle | 180° | |

| Max. Towing speed | 60 m/ min | 110 m/ min |

| Max. Bending speed | 800°/s | 1000°/s |

| Length accuracy | ±1mm | |

| Angle accuracy | ±1° | |

| Average power | 5kw/ h | |

| Pcs processed | ≤2 | |

| Total power | 15 kw | 28 kw |

| Working temperature | (-5°~40°) | |

| Total weight | 1350 kg | 2200 kg |

| Main color | Gray+ orange (or customized) | |

| Machine size | 3280* 1000* 1700 mm | 3850* 1200* 2200 mm |

Please send inquiry with your specifications, so that we can make solution for you accordingly;

Accessory equipment:

| Wire payoff | Collect rack |

Finished Product:

Steel Rebar Stirrup Bending Machines are often used for bending angle accuracy. This machine is suitable for bending various steel bars for construction. Different types of bending machines are used in the construction industry to bend steel bars. All types of bending machines differ in design and engineering, strength, technology and purpose. In addition to bending steel bars, different machines offer unique features and abilities depending on the tasks they need to perform. It can be used in the construction industry for scaffolding safety hooks, ceiling hooks, concrete, and in the railway industry, including railway clips.

Sales-after service

|

We will provide a full set of installation videos about the concertina razor barbed wire making machine

|

Provide the layout and electrical diagram of the concertina barbed wire production line |

Provide installation instruction and manual for automatic security razor wire machine |

Answer every question online 24 hours a day and talk to professional engineers |

Technical personnel go abroad to install and debug razor barbed tape machine and train workers |

A:Lubrication liquid is added regularly.

B:Checking electric cable connection every month.

Certification

FAQ

Q: How do i produce different shape of bending wire?

A: You can choose shape from PLC system, easily operation;

Q: How much is wire material coils bearing?

A: Max. 2 T.

Q: How much labor required for this machine?

A: 1 is enough.

If above FAQ did not solve your problem, please contact us directly