Wire Straightening and Cutting Machine

GT2-3.5H

GT3-6H

GT3-8H

GT6-12H

● full automatic

● CNC control

● Different types of machines suitable for different wire diameters;

● High working speed, can be 130M/min.

Our wire straightening and cutting machine is designed by our engineer and has high speed. We can supply different types of wire straightening and cutting machine which is suitable for different wire diameter and cutting lengths.

Advantages:

1. Simens PLC+touch screen, Schneider electric parts, working stable.

2. The wire traction adopts a pneumatic device, guaranteeing high speed.

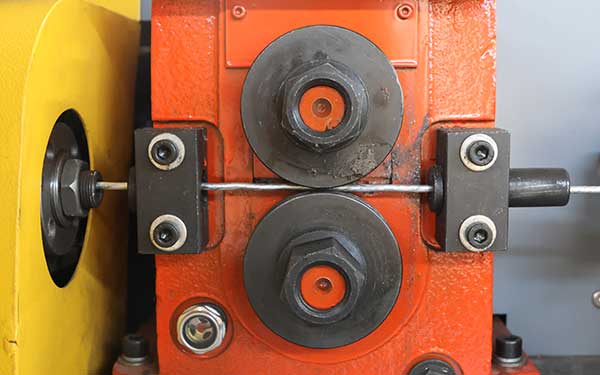

3. Straightening tube with straightening dies (YG-8 alloy steel material) inside, working long life.

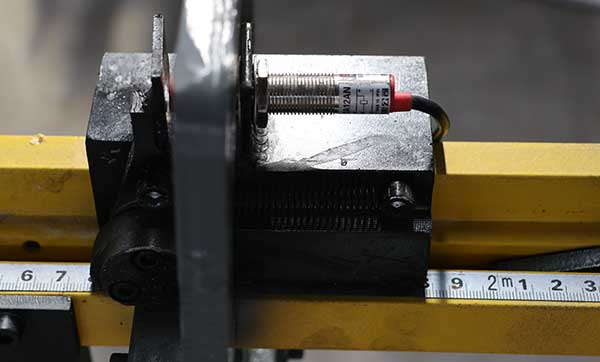

4. Wire cutting length can be adjusted on the falling bracket.

Machine Parameter:

|

Model |

GT2-3.5H |

GT2-6+ |

GT3-6H |

GT3-8H |

GT4-12 |

GT6-14 |

GT6-12H |

|

Wire diameter(mm) |

2-3.5 |

2-6 |

3-6 |

3-8 |

4-12mm wire rod, 4-10mm rebar |

6-14mm wire rod, 6-12mm rebar |

6-12 |

|

Cutting length(mm) |

300-3000 |

100-6000 |

330-6000 |

330-12000 |

Max. 12000 |

Max. 12000mm |

Max. 12000 |

|

Cutting error(mm) |

±1 |

±1 |

±1 |

±1 |

±5 |

±5mm |

±5 |

|

Working speed(M/min) |

60-80 |

40-60 |

120 |

130 |

45 |

52M/min |

Max.130 |

|

Straightening motor(kw) |

4 |

2.2 |

7 |

11 |

11 |

11kw |

37 |

|

Cutting motor(kw) |

---- |

1.5 |

3 |

3 |

4 |

5.5kw |

7.5 |

The wire after straightening and cutting is usually used for welding the fence mesh or in construction site directly

Sales-after service

|

We will provide a full set of installation videos about the concertina razor barbed wire making machine

|

Provide the layout and electrical diagram of the concertina barbed wire production line |

Provide installation instruction and manual for automatic security razor wire machine |

Answer every question online 24 hours a day and talk to professional engineers |

Technical personnel go abroad to install and debug razor barbed tape machine and train workers |

Equipment maintenance

|

A. Lubrication liquid is added regularly. B. Checking electric cable connection every month. |

Certification

FAQ:

Q: What's the delivery time of the machine?

A: About 30 days after received your deposit.

Q: What's the payment terms?

A: 30% T/T in advance, 70% T/T before shipment, or L/C, or cash etc.

Q: How many persons to work the machine?

A: One worker can operated 1 or two machines.

Q: How long of the guarantee time?

A: One year since the machine was installed at buyer's factory but within 18 months against B/L date.